软件与数字系统 Software & Digital Systems

智能化增材制造全流程控制 Intelligent Additive Manufacturing Full Process Control

从专业切片算法到远程集群管理,提供简单易用且功能强大的软件支撑。 From professional slicing algorithms to remote cluster management, providing simple yet powerful software support.

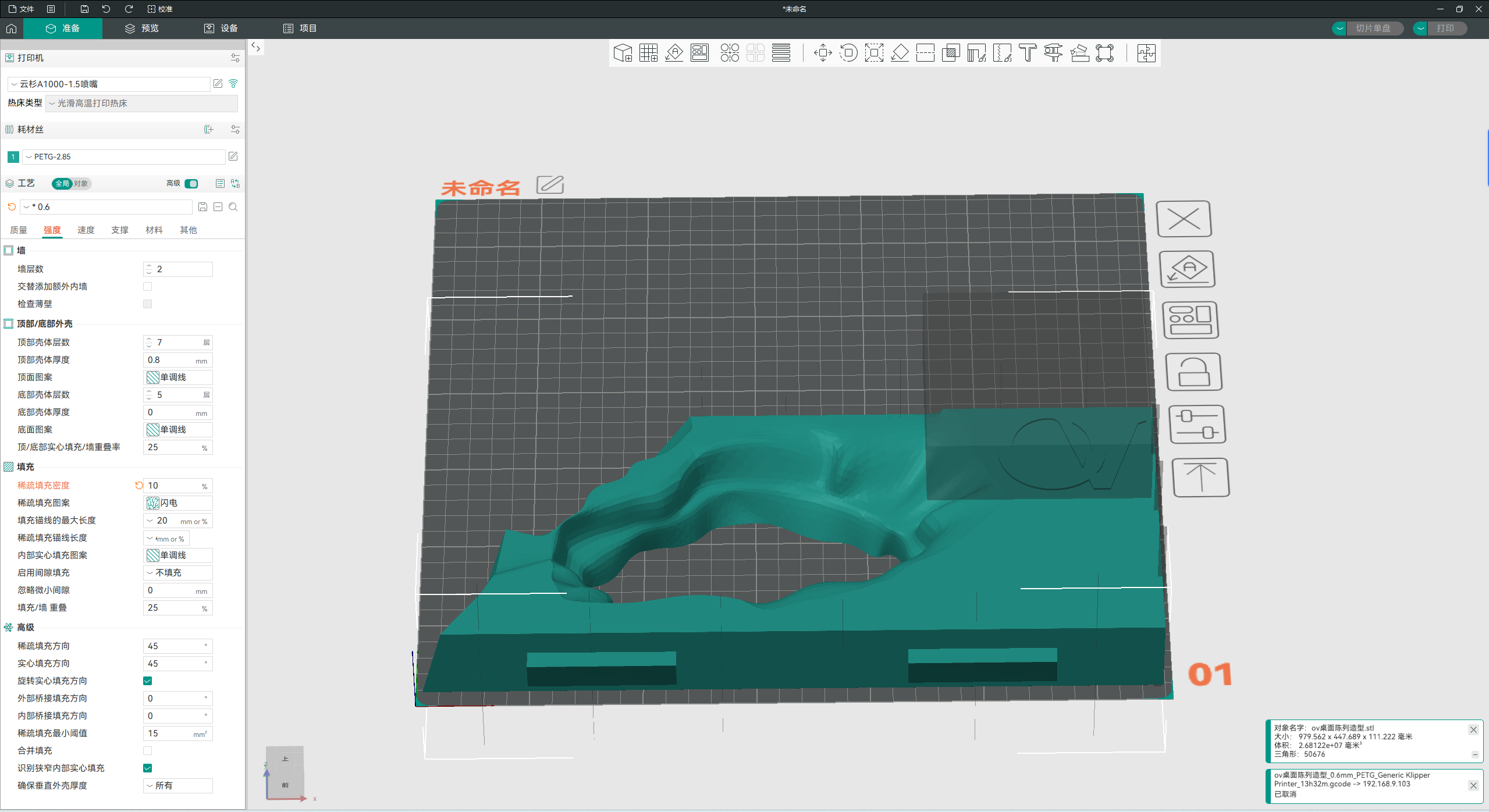

云杉定制切片软件 Yunshan Custom Slicing Software

针对大尺寸 FGF/FDM 深度优化的工艺包 Process packages deeply optimized for large-scale FGF/FDM.

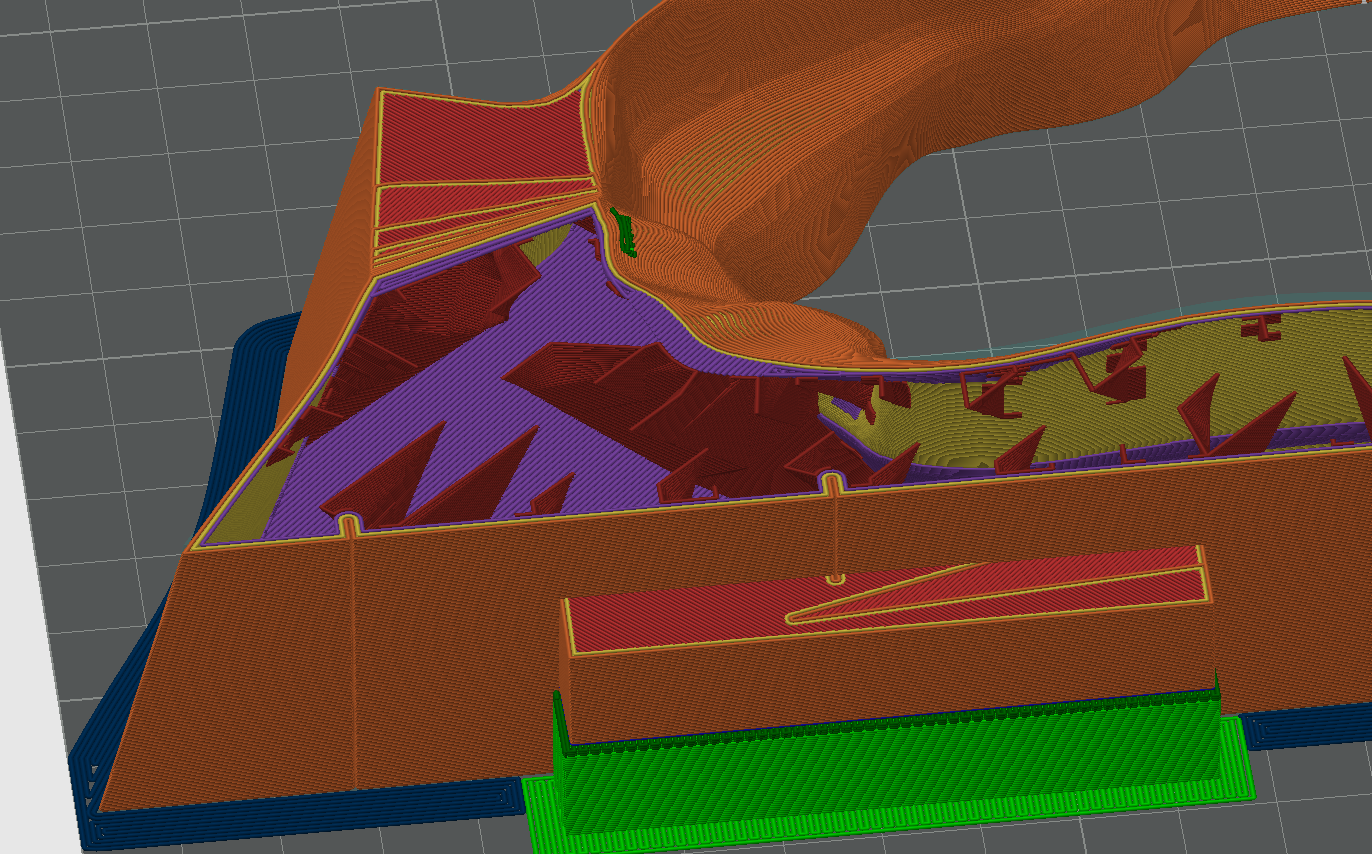

智能切片算法 Intelligent Slicing Algorithm

内置针对大型零件的收缩率补偿、层间温度控制与变路径宽度策略,确保打印成功率。 Built-in shrinkage compensation, interlayer temperature control, and variable path width strategies for large parts, ensuring printing success.

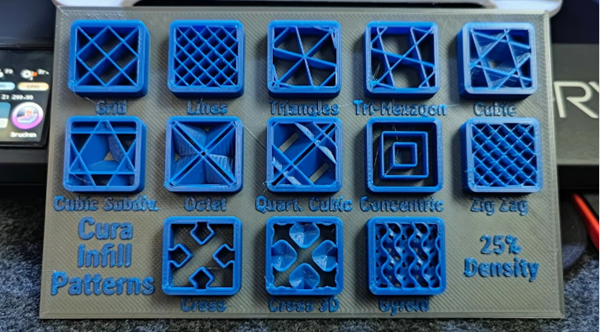

多种填充模式 Various Infill Patterns

提供高刚性、轻量化等多种工业级填充方案,满足不同场景下的力学强度需求。 Offering multiple industrial-grade infill schemes like high-rigidity or lightweighting to meet mechanical strength needs.

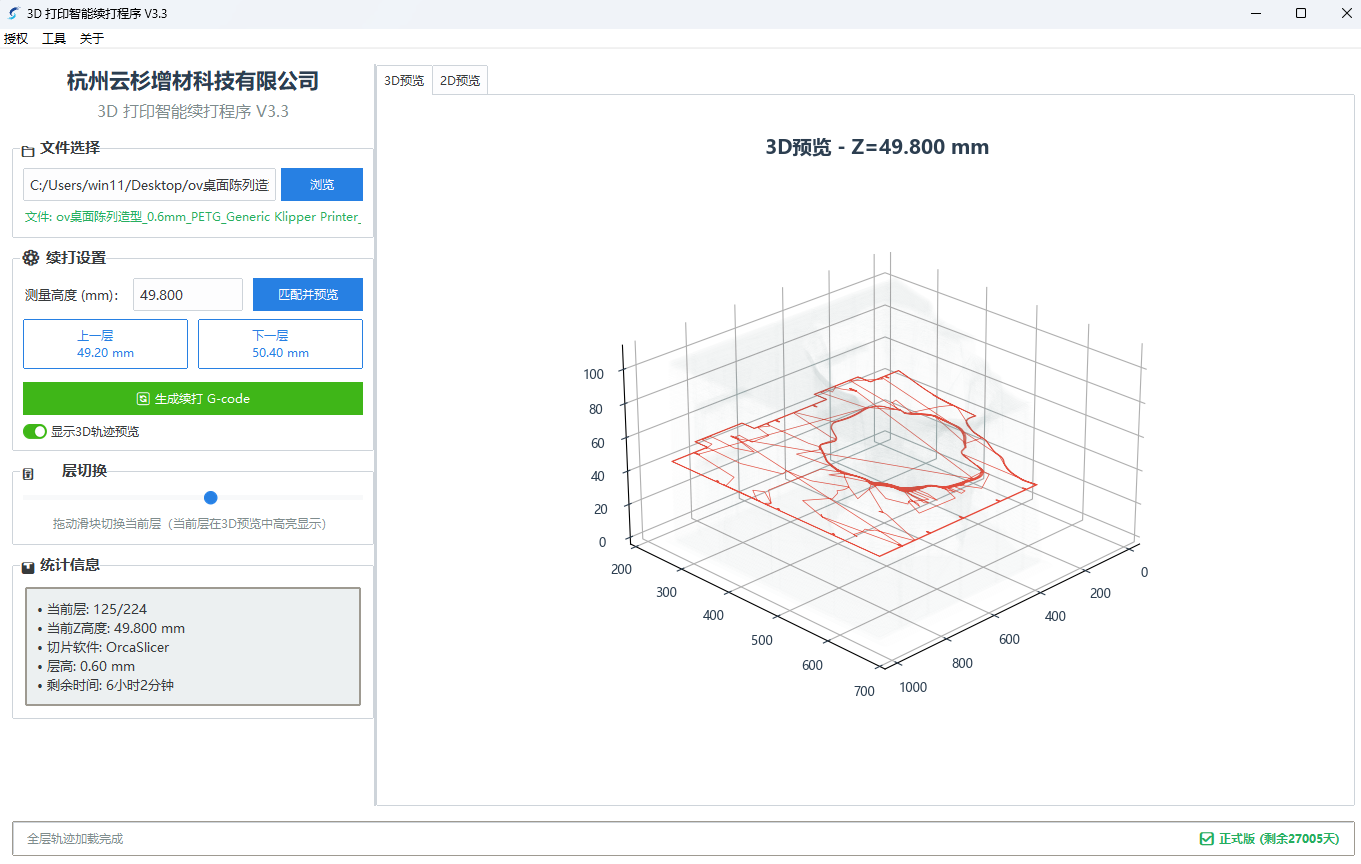

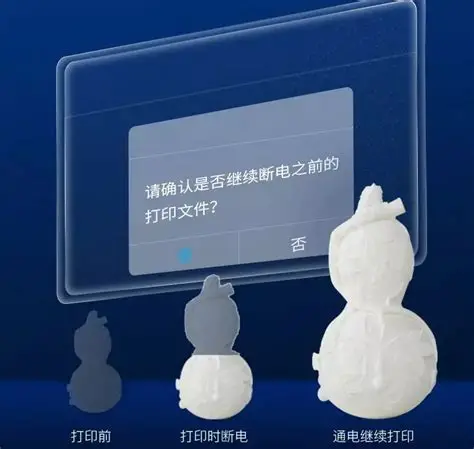

自主研发智能续打软件 (专利技术) Self-developed Intelligent Resumption Software (Patented)

解决大尺寸打印意外中断痛点,支持 G-Code 深度可视化 Solving the pain point of accidental interruption, supporting G-Code deep visualization.

G-Code 2D/3D 可视化预览 G-Code 2D/3D Visualization Preview

强大的可视化引擎,支持在打印前及打印过程中对 G-Code 路径进行实时 2D 平面及 3D 立体预览,直观把控成型细节。 A powerful visualization engine supporting real-time 2D plane and 3D stereo preview of G-Code paths before and during printing.

核心硬件控制系统 Core Hardware Control System

软硬深度结合,保障大型工件的打印成功率 Deep software-hardware integration ensuring success for large workpieces.

自动断电续打与断料检测 Auto Power-off Resumption & Filament Detection

系统集成高灵敏度传感与数据保护模块。遭遇突发断电时,软件自动保存当前坐标;检测到断料时,设备自动暂停并报警。确保大型工件接续无痕,彻底杜绝材料浪费。 Integrated with high-sensitivity sensing and data protection. Saves coordinates on power failure and pauses on filament run-out, ensuring seamless resumption.

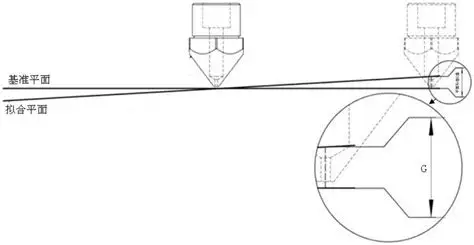

智能自动调平系统 Intelligent Automatic Leveling

基于高精度传感器的全自动调平算法,动态补偿打印平台微小形变。尤其针对大尺寸平台,确保首层成型完美贴合,大幅提升打印成功率与工件精度。 Full-automatic leveling algorithm based on high-precision sensors, dynamically compensating for platform deformation to ensure perfect first-layer adhesion.

工业物联网云平台 Industrial IoT Cloud Platform

打破物理局限,实现生产流程的透明化管理 Breaking physical limits, achieving transparent management of the production process.

远程监控与诊断 Remote Monitoring

实时查看打印进度与摄像画面,支持远程参数微调与设备状态诊断。 Real-time view of printing progress and camera feed, supporting remote parameter fine-tuning and status diagnosis.

任务集群管理 Cluster Management

一键分发任务至多台设备,优化多设备并行生产效率,实时统计生产工时与材料消耗。 One-click task distribution to multiple devices, optimizing parallel production and tracking work hours and material consumption.

OTA 在线升级 OTA Updates

定期推送最新的运动控制算法与材料工艺包,让您的设备始终处于最佳工作状态。 Regularly pushing the latest motion control algorithms and process packages to keep your equipment at its best.